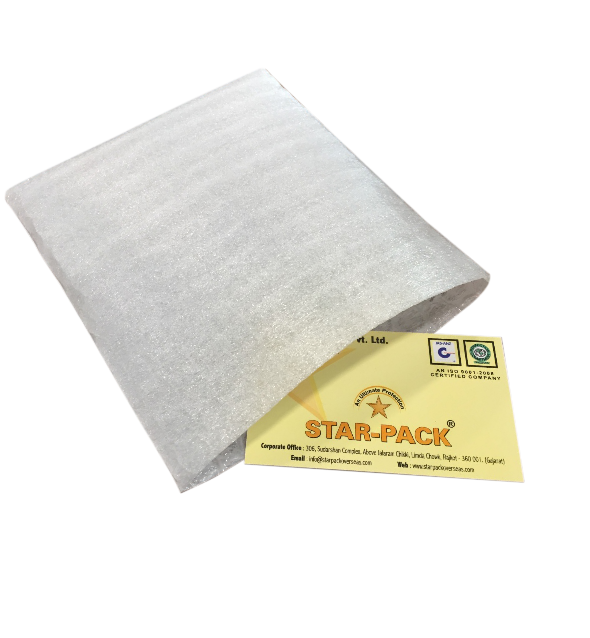

EPE FOAM BAG is made by bending one side and sealing two sides of epe foam. Used to protect precious products. Different sizes and qualities are available as per customers requirement.

Also available in one side or both side laminated for extra-ordinary look and fast packing purpose.

Features :

- Durable, light weight & non dusting.

- Flexible & elastic – Easy to cut, fabricate, wrap around, insert or seal.

- Can take care of multiple shocks unlike rigid foams.

- Non-toxic & odorless. No CFC/HCFC gases are used during production.

- EPE Foam Roll/Sheet is 100% recyclable environment friendly foams.

- Offers excellent resistance to moisture, fungi & chemicals.

- EPE Foam as high buoyancy and relatively higher mechanical strength.

- Special HMHD film laminated foams, anti-static PE foams, mattress foam also available.

Applications :

- Packaging solutions: Dust covers,bubble wrap, corner pads, support pads,

EPE buffers – customized foam packaging buffers, encapsulation blocks,

display usage etc. Anti-static packaging covers. - Packaging of consumer durable and white goods like TV covers,

Refrigerator packaging, LCD / LED packaging etc. - Packaging and cushioning solutions for Automobiles: Carpet underlays,

gaskets, seat cushion inserts, door liners, side / roof panels etc. - Transit packing of vehicles, returnable / multiple use packing material,

domestic and exports spares packing, component packing,

packing material for 2-wheeler, steering wheel covers, windshield covers,

die-punch wheel arch pads etc. - Packing material for painted surface of components

Sports & recreation goods: Protective foam gears (Arm / elbow / leg / shoulder pads),

PE foam mats and mattresses, garment insulation, helmet lining life jackets / life vests,

sleeping bag underlay, shoe insoles, gloves, ski belts and many more… - Packaging of electronics & machinery

Fragile item packaging – packaging of glass sheets, glassware, mirrors,

picture frames, ceramics, chinaware, pottery, handicrafts etc.

| Specification | ||

|---|---|---|

| Density | Kg/m3 | 25 to 45 |

| Tensile Strength at ambienttemp | Kg/m3 | MD 2.5 to 5 TD 1.8 to 3.5 |

| Elongation | % | MD 80 to 100 TD 42 to 70 |

| Compression Strength at 10% | Kg/m2 | 0.05 to 0.20 |

| Water absorption after 96 hrs | Volume | 0.01 to 0.50 |

| Water Vapour Transmission | Gm/m3 | 20 to 25 |

| Buoyancy (Fresh Water) | Kg/m3 | 915 to 940 |

| Thermal C conductivity | k/ca/M.Hr.c | 0.020 to 0.028 |

| Service Temperature | oc | -50 to +70 |